Source: unsplash.com

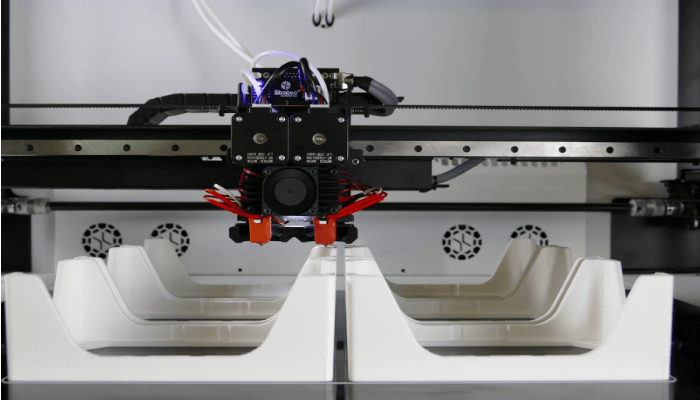

The introduction of 3D printing technology marked a significant turning point for manufacturing and prototyping as it enabled conversion from digital designs to tangible objects in three dimensions. This innovation’s disruptive impact on several industries has been remarkable from its inception until today.

The groundbreaking invention sparked widespread interest amongst enthusiasts ranging from hobbyists to enthusiastic entrepreneurs alike who are fascinated by its potential. Our beginner’s guide aims to provide helpful information on methods for getting started and explore vital early-stage steps into this fascinating new era in production design.

Understanding 3D Printing

At its core, 3D printing (also known as additive manufacturing) involves the use of digital models to create physical objects through successive layers, or “prints.” Compared with earlier traditional materials-related techniques largely based on “subtractive” processes such as cutting or reshaping material while eliminating excesses rather than adding them, this new transformative innovation precisely does the opposite—building up material gradually.

As a result of these technological advances, unprecedented possibilities for customization offer unparalleled design freedom while enabling rapid prototyping capabilities, lending themselves well to introducing intricate designs and complicated geometries previously deemed impossible.

The applications of 3D printing are vast, encompassing numerous industries. In product design and development, this technology facilitates rapid iterations and the creation of functional prototypes. In healthcare, it has brought about a revolution in medical device manufacturing, the production of patient-specific implants, and advancements in organ printing research.

Architects and engineers utilize 3D printing to craft intricate models and showcase their designs. Moreover, it has found practical uses in education, jewelry making, fashion, and art, pushing the boundaries of creativity and enabling innovative approaches. The versatility of 3D printing continues to expand, opening up endless possibilities across diverse sectors.

Source: unsplash.com

The 3D Printing Process

When starting 3D printing, there are several steps to follow. First, you must create or obtain a 3D model using computer-aided design (CAD) software. There are many options available for CAD programs to cater to all levels of expertise. Once your model is ready, it must be sliced into thin layers using slicing software. This step is critical to determining the path and instructions the 3D printer will follow.

Once your model is sliced into layers, you can select the appropriate material for your print. The choices include plastic (such as PLA or ABS), resin, food-based materials, and metal. In the latter, metal powders are integral to the layer-by-layer deposition process used to create solid metal objects. Therefore, it is vital you choose carefully as different materials may require a different printing process.

With everything set up, it’s time to print! Load your chosen material into the 3D printer and start printing away. The printer will create the object layer by layer according to the instructions provided by the slicing software. Once the printing is complete, remove your object from the printer carefully.

Post-processing, such as cleaning, sanding, or painting, may be required depending on what you intend to use it for and its desired finish or cleanliness level.

Choosing A 3D Printer

The selection process for choosing a suitable 3D printer, especially if you are a beginner, depends heavily on multiple factors paramount to meeting individual needs optimally. Firstly, check for high-quality print features, as they determine the accuracy and intricate details presented on finished prints generated from this product. Another crucial consideration is the build feature, which determines the size of objects a printer can comfortably accommodate within its adjustable parameters.

The time taken to complete any print job is also essential to keep in mind when investigating printing speeds before purchase. Lastly, ascertain what machine materials are used and compare your relevant project requirements before deciding on a final investment model. Reading existing reviews and conducting research aid in guaranteeing a well-informed decision consistent with your budget and specific needs.

Discovering new horizons for creators, innovators, and problem solvers alike is one of the exciting possibilities offered by the growing field of 3D printing. But before delving too deeply into advanced techniques or applications that can be accomplished using this technology, make sure you first understand its foundational mechanisms, explore ways it has been successfully used across various industries, and become proficient with each step required to bring prints from idea to reality.

With rapid progressions occurring daily on both material development fronts and hardware improvements themselves, there couldn’t be a better time for curious hands-on learners like yourself to gain confidence through experience with three-dimensional printing possibilities.